|

Center for Nonlinear Studies |

Activities of the NMSU Computational Mechanics of Materials and Structures (cMMS) lab are focused on modeling and simulation of linear and non-linear responses of materials and structures including but not limited to:

- contribution of irregularly-shaped defects and inclusions to the effective thermo-mechanical properties of heterogeneous materials

- overall response of materials reinforced with unidirectional and curved fibers

- processing-induced residual stresses in woven composites

- behavior of biomechanical structures

- generation of complex microstructures

- etc.

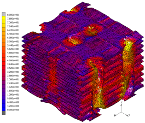

In this presentation, an overview of the main lab activities will be presented and the ongoing NSF-sponsored project (CMMI-1662098) will be discussed in detail.The ultimate goal of the NSF project is to develop a method combining high fidelity Finite Element (FE) models with experimental measurements to enable estimation of volumetric distributions of manufacturing-induced residual stresses in 3D woven composites. The method will be utilized to understand and mitigate the effects of the stresses. Our hypothesis is that development of the residual stresses is primarily driven by the mismatch in the coefficients of thermal expansion between the constituent materials – epoxy matrix and carbon fiber – during cooling from curing to room temperature. Effects of reinforcement geometry and constitutive matrix material model are discussed.

|  |  |  |

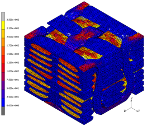

Left to right: microtomography data used to generate a realistic FE model of an orthogonal 3D woven composite; volumetric FE mesh of the reinforcement tows; stress component

Host: Alan Hurd